If your thermal machine (brushcutter, edger, hedge trimmer or chainsaw) no longer starts correctly. This means that engine oil and petrol have been sucked into the cylinder and have interfered with the correct functioning of the compressed air. Since the combustion chamber is wet up to the spark plug, the electric arc cannot strike between the spark plug electrodes. This problem is frequently due to the wrong startup procedure or simply a bad startup.

Table of Contents :

Case of a drowned brushcutter

Procedure to follow to try to restart your thermal machine (drowned brushcutter):

- Let your thermal machine (brushcutter, edger, hedge trimmer or chainsaw) rest for a while. Approximately 15 to 30 minutes to allow oil or petrol to drain from the cylinder.

- Remove the spark plug. Try cranking your machine without its spark plug by pulling the starter cable several times evenly to evacuate the remaining oil or fuel in the cylinder.

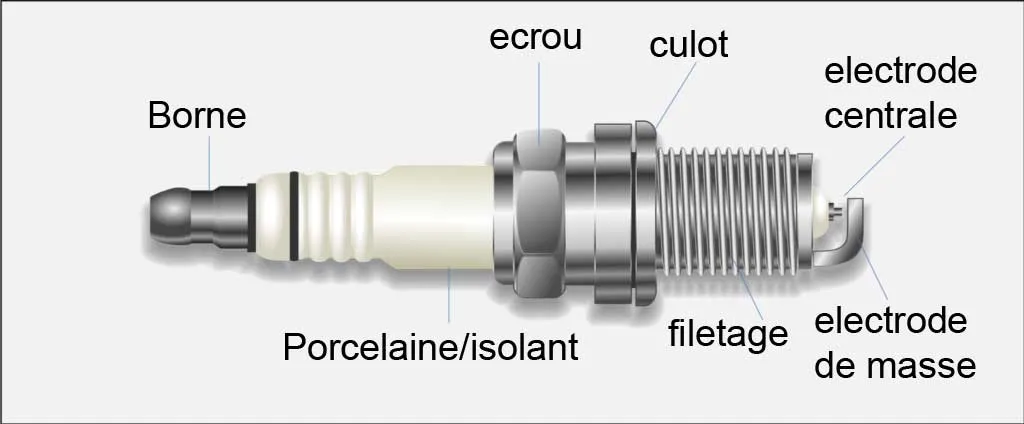

- Clean and dry the spark plug. Then check if the spark plug is sparking again (if it is not dead). To do this, reconnect your dried candle by inserting its tip (terminal) into the terminal. Hold the spark plug base or thread against any metal (electrically conductive) part of the machine (cylinder, cylinder head, etc.). Operate the engine starter cable and see if there are sparks between the center electrode and the ground electrode.

- If you find that your brushcutter’s spark plug is dead, buy a new spark plug and put it back in place. You should then attempt to run your trimmer as normal.

If your brushcutter still doesn’t seem to work, it might be a good idea to have it repaired at a repair shop. But it’s worth noting that repairs to a drowned brushcutter can be a bit expensive.

How do you unflood a brushcutter (drowned brushcutter)?

If you have noticed that your brushcutter’s spark plug is dry and won’t start, there are several possible reasons for this and therefore several steps you can take to resolve the problem.

Reasons and procedure or indications to follow:

- The position of the Starter: check and see if the Starter is in the correct position for the type of start you are performing. For a cold start (cold engine) of a brushcutter, the lever must be in the “Choke” position (in the upper position). In the context of a warm start (hot engine), place the lever in the central position.

- Spark Ignition System (Petrol Engine): Obstructions in the carburetor or absence of an electric arc (spark) that flashes between the electrodes of a spark plug in the combustion chamber. Check and clean the carburetor according to the instructions in the owner’s manual. See Unusual checks.

- The air filter: the air filter can become dirty and clog the air entering the combustion chamber. So, it is important to clean the air filter or replace it if necessary.

- The fuel system: lack of fuel or clogged fuel filter. Make sure the fuel tank is full, and the fuel filter is not clogged. If the filter is clogged, it should be cleaned or replaced if necessary.

- The ignition circuit: the degraded state of an ignition cable or its bad connection to the coil or to the spark plug can lead to the failure to start a petrol engine.

- Ignition Coil: Assess the proper condition of the ignition coil and the ignition cable if it is in good condition and correctly connected.

- Compression : check the compression of your brushcutter. Engine compression can influence the starting of a petrol engine. If the compression is low, it may be necessary to check the piston rings or rings. The rings may be broken or stuck at the piston.

However, if you have difficulty starting your brushcutter despite these checks and instructions to follow, it is best to call on a brushcutter maintenance and repair professional to help you.

Additional tips

Here are some additional tips to help you anticipate starting problems and extend the life of your brushcutter:

- Always store your brushcutter in a dry and secure place to avoid any damage caused by rain, snow or bad weather.

- Clean your brushcutter after each use to remove plant debris, liquids, and mud.

- Always use the correct fuel mixture (petrol and engine oil) to keep your brushcutter engine running properly.

- Inspect and replace worn parts such as spark plugs, air filters, and fuel filters to prevent common starting problems and breakdowns.

If you have any questions about the use or maintenance of your brushcutter, do not hesitate to consult its user manual or call a professional for assistance.

For spare parts: